Spherical Graphite Rolls

These are one of the most versatile materials now-a-days. In this free carbon takes the shape of spheroids or nodules, thereby eliminating the notch effect of flake graphite and improving upon the mechanical properties of the cast iron. These can be controlled from fine pearilite to bainite or even to martensite.

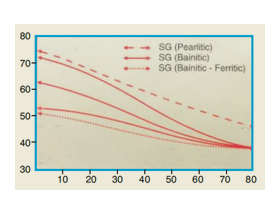

S.G. Pearlitic

These are basically a combination of free carbide and hard matrix. These characteristics give the roll good hardness penetration.

Application

Suitable for small to medium sections billets, Rolling flat and wire rod.

S.G. Accicular

These rolls are stronger and more wear resistant than S.G. Pearlitic rolls and are capable of a higher hardness, especially in depth. These properties are produced by increasing the alloy content mainly nickel, molybdenum and chromium modifying the matrix structure from pearlitic to an accicular form.

Application

Wire rod, Bar, Coil and medium section mills

| Grade | HS Range | C | Mn | Si | Cr | Ni | Mo | S | P | UTS Kgf/mm. Sq. |

|---|---|---|---|---|---|---|---|---|---|---|

| Pearlitic | 50-60 | 3.00 3.40 |

0.30 0.60 |

1.50 2.20 |

0.20 0.60 |

1.40 1.80 |

0.25 0.40 |

0.015 Max. |

0.10 Max. |

50-60 |

| 60-65 | 3.20 3.50 |

0.60 1.00 |

1.40 1.70 |

0.30 0.60 |

1.50 2.00 |

0.35 0.55 |

0.015 Max. |

0.10 Max. |

50-60 | |

| Acicular (specially TMT) & small sections |

65-70 | 3.10 3.50 |

0.50 0.80 |

1.30 2.00 |

0.30 0.80 |

2.60 3.00 |

0.80 1.10 |

0.015 Max. |

0.075 Max. |

50-70 |

| 70-75 | 3.10 3.50 |

0.50 0.80 |

1.30 2.00 |

0.30 0.80 |

2.80 3.20 |

0.80 1.10 |

0.015 Max. |

0.075 Max. |

50-70 |